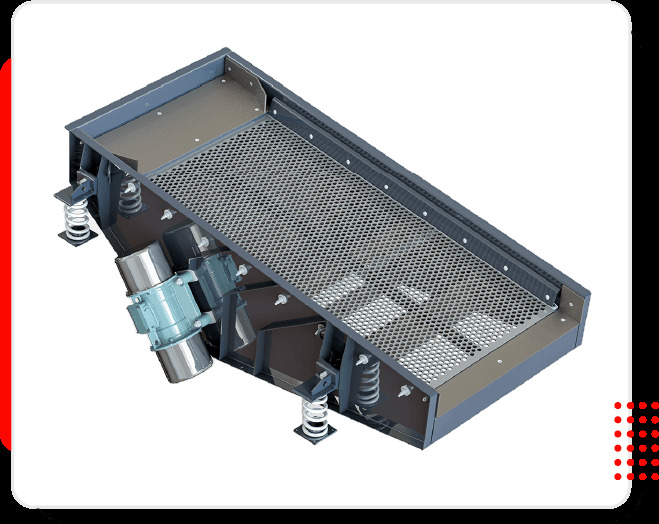

Linear Rectangular Vibro Screen - Precision Screening for Bulk Materials

Price 185000 INR/ Piece

MOQ : 1 Piece

Linear Rectangular Vibro Screen - Precision Screening for Bulk Materials Specification

- Usage

- Industrial

- Material

- Stainless Steel

- Size

- Standard

- Condition

- New

- Color

- Silver

- Power Mode

- Electric

- Voltage

- 240 Volt (v)

- Power Consumption

- 2 Horsepower (HP)

Linear Rectangular Vibro Screen - Precision Screening for Bulk Materials Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 500 Pieces Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Linear Rectangular Vibro Screen - Precision Screening for Bulk Materials

Order the Linear Rectangular Vibro Screen for precision screening of bulk materials and experience remarkable efficiency in your industrial processes. Highlighted by its robust stainless steel construction and crackerjack engineering, this renowned machinery operates at 240 Volt (v) using just 2 HP. Suitable for new installations, its electric power mode ensures consistent performance. The standard size fits various industrial settings, with a sleek silver design. Manufactured, supplied, and serviced in India, order today for streamlined sorting handled by a trusted manufacturer, service provider, and supplier.

Advantageous Industrial Screening Solution

The Linear Rectangular Vibro Screen is distinctly advantaged for bulk material precision screening. Used as a reliable tool in industries requiring consistent size separation, it accommodates various application media such as powders and granules. Its remarkable accuracy and robustness make it a preferred choice in manufacturing, chemical, and food processing sectors, ensuring efficient throughput.

Certifications and Market Valuation

This vibro screen holds required certifications, assuring quality and compliance for domestic markets across India. Major shipments are executed from specified FOB ports, guided by client purchase orders. Valuation is performed with transparency, meeting industrial standards. Ensure precise documentation and seamless procurement for every order, reinforcing confidence in each transaction.

Advantageous Industrial Screening Solution

The Linear Rectangular Vibro Screen is distinctly advantaged for bulk material precision screening. Used as a reliable tool in industries requiring consistent size separation, it accommodates various application media such as powders and granules. Its remarkable accuracy and robustness make it a preferred choice in manufacturing, chemical, and food processing sectors, ensuring efficient throughput.

Certifications and Market Valuation

This vibro screen holds required certifications, assuring quality and compliance for domestic markets across India. Major shipments are executed from specified FOB ports, guided by client purchase orders. Valuation is performed with transparency, meeting industrial standards. Ensure precise documentation and seamless procurement for every order, reinforcing confidence in each transaction.

FAQ's of Linear Rectangular Vibro Screen - Precision Screening for Bulk Materials:

Q: How does the Linear Rectangular Vibro Screen enhance material sorting efficiency?

A: The Linear Rectangular Vibro Screen uses precision vibration technology, allowing bulk materials to be reliably sorted by size, leading to improved output quality and reduced processing time in industrial applications.Q: What industries can benefit from using this vibro screen?

A: Industries such as food processing, chemicals, manufacturing, and pharmaceuticals greatly benefit from its crackerjack screening performance, thanks to its versatility with various powders and granulates.Q: Where is the Linear Rectangular Vibro Screen manufactured and supplied?

A: It is proudly manufactured, distributed, and serviced within India by a renowned team known for quality and durability.Q: What is the process for placing a purchase order and shipment?

A: Place a purchase order directly with the supplier. Shipment is organized from designated FOB ports, ensuring proper packaging and timely delivery to the required destination.Q: When should industrial facilities consider upgrading to this vibro screen?

A: Facilities should upgrade when seeking remarkable efficiency, improved material grading precision, or when replacing outdated screening systems to meet advanced production standards.Q: How is the usage of this screen evaluated for suitability?

A: Valuation considers the material type, screening volume, and industry standards. The supplier provides consultation to ensure it matches operational needs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry